Latvian EMS company

We provide better

quality, flexibility and speed

than any other EMS in the Nordic region.*

quality, flexibility and speed

than any other EMS in the Nordic region.*

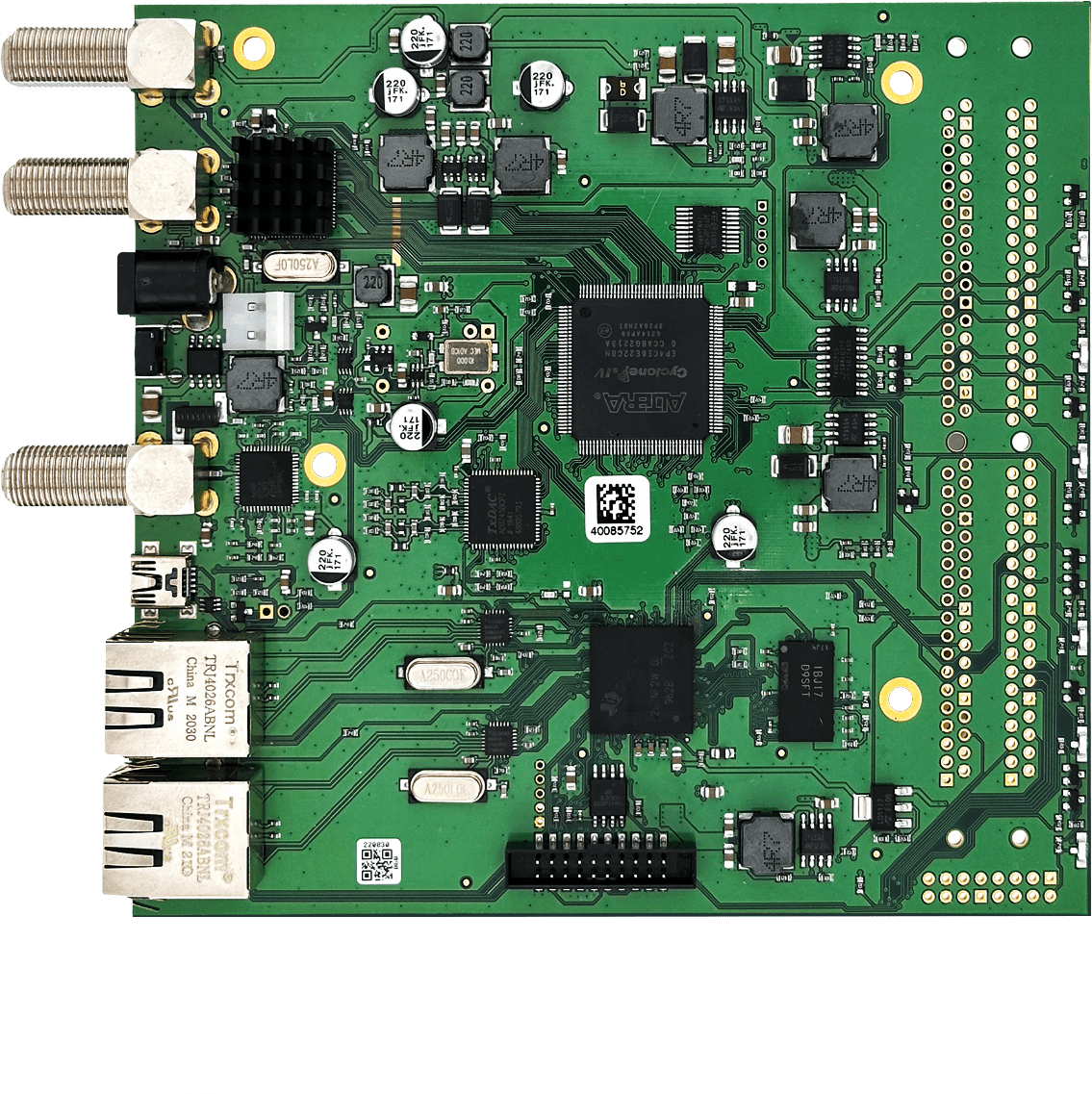

Automatic surface mount assembly (PCBA) with up to 24 layers and capacity of 226,000 c/h

Automatic optical 3D inspection (AOI) & X‑Ray inspection

Mechanical case assembly, ultrasonic welding, 3D printing

Firmware upload, verification, calibration and environmental testing of products

* Based on multi-year customer satisfaction reviews

Certification